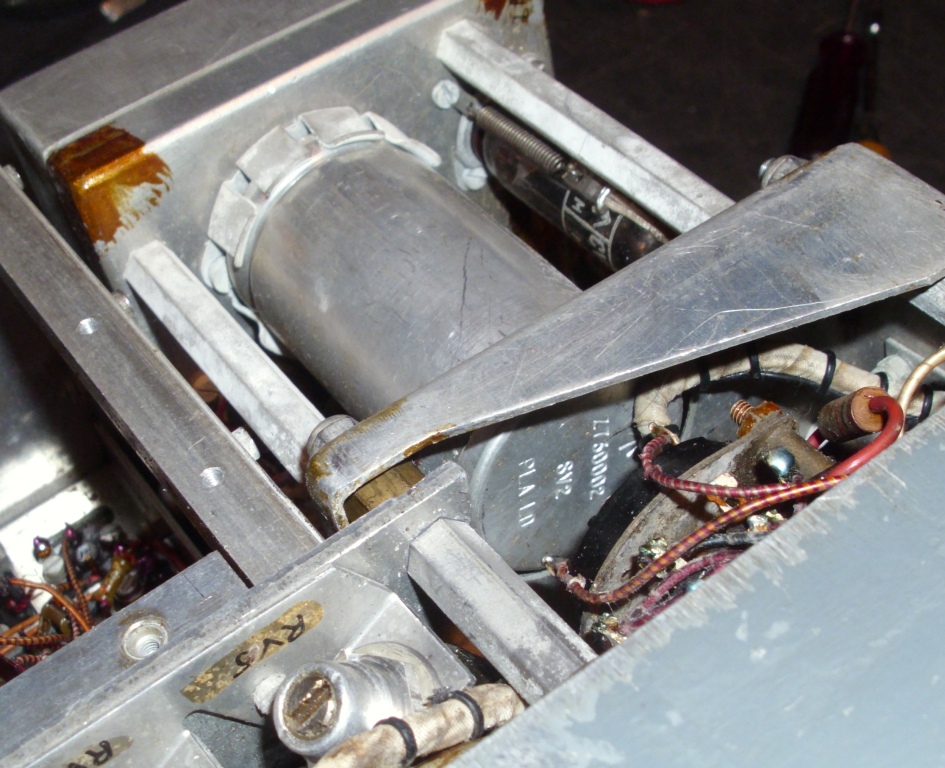

At one stage, serious smoke erupted from the unit, initiating a panic turn off.

There is a series R and C circuit across the HT secondary. C49 had short

circuited, and burnt up R65, which released the large amount of smoke.

The fuse eventually blew, but not in time to save the resistor.

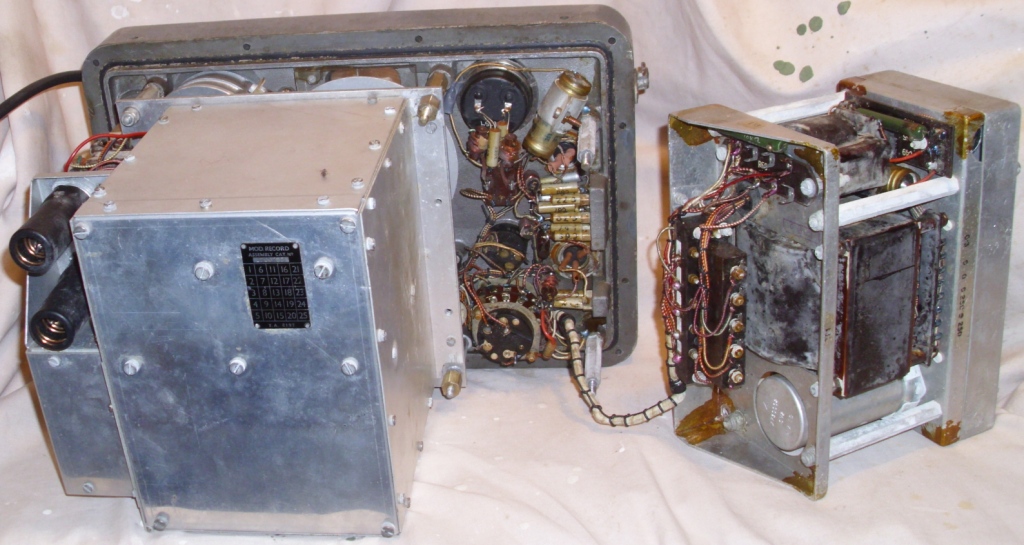

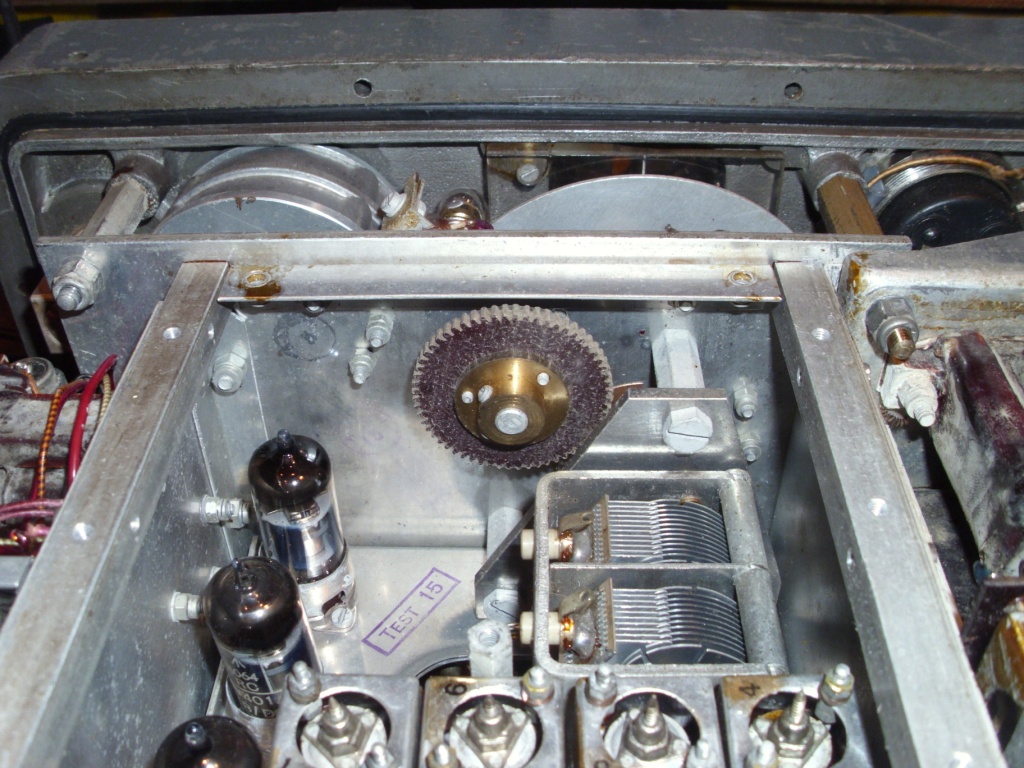

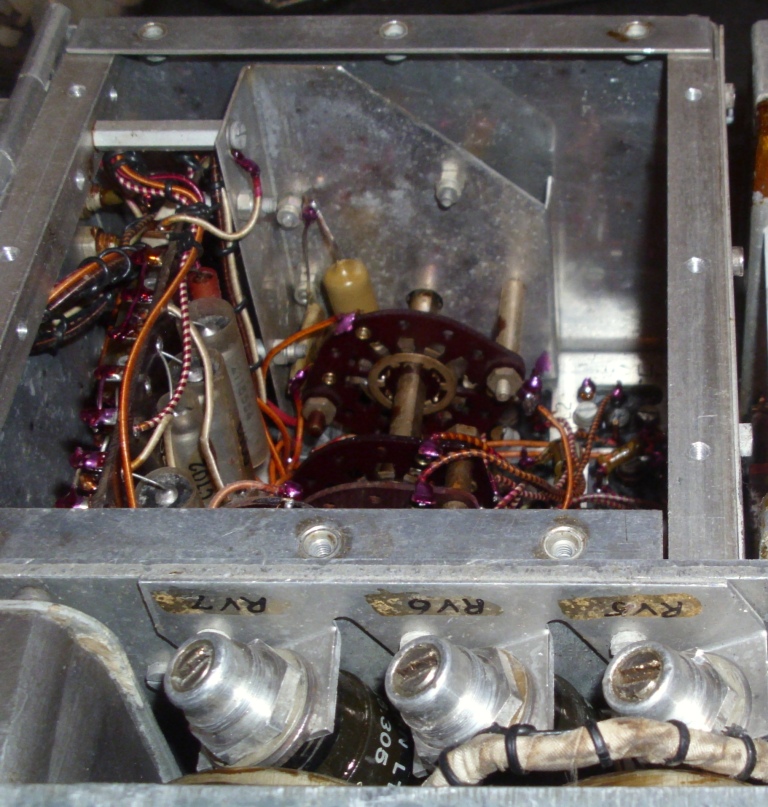

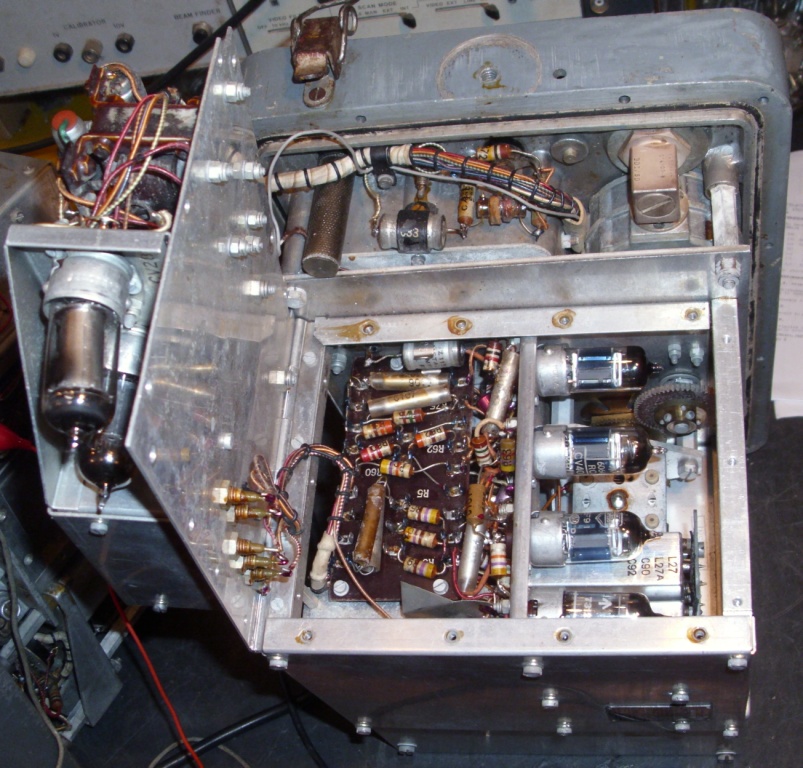

OSCILLATOR MODULE

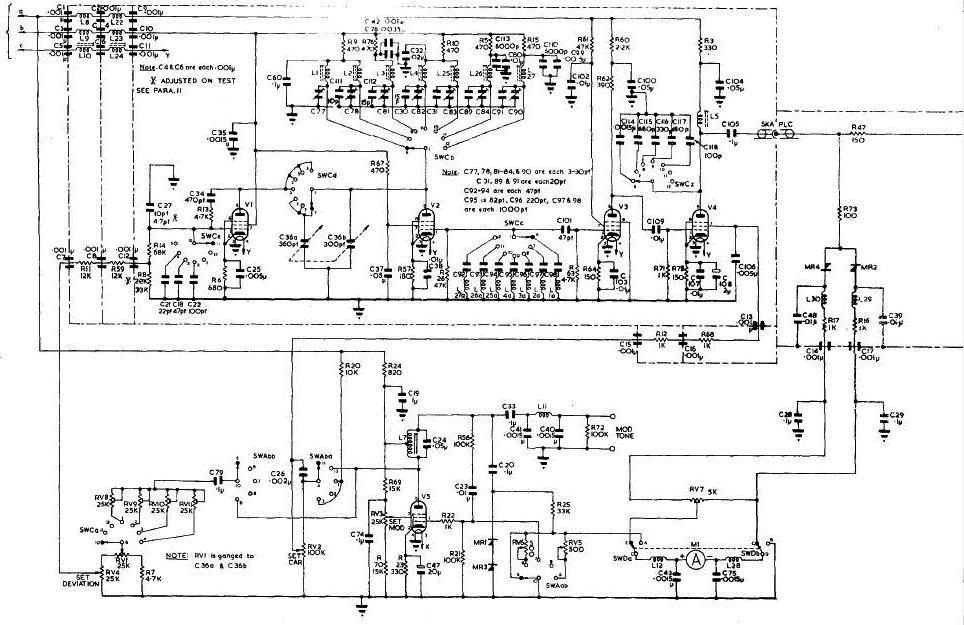

The oscillator is functionally arranged as two sections. The RF oscillator

is contained inside a closed metal box. The AF oscillator is on the outside

of this box. There is also a regulator that produces 150 volts DC for the RF

oscillator.

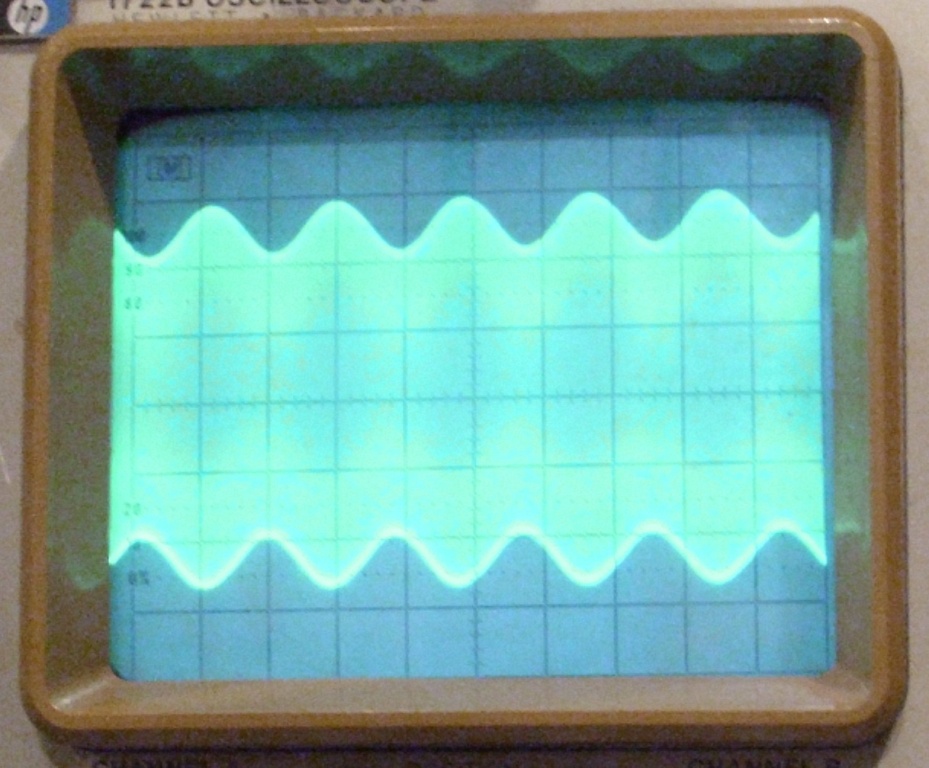

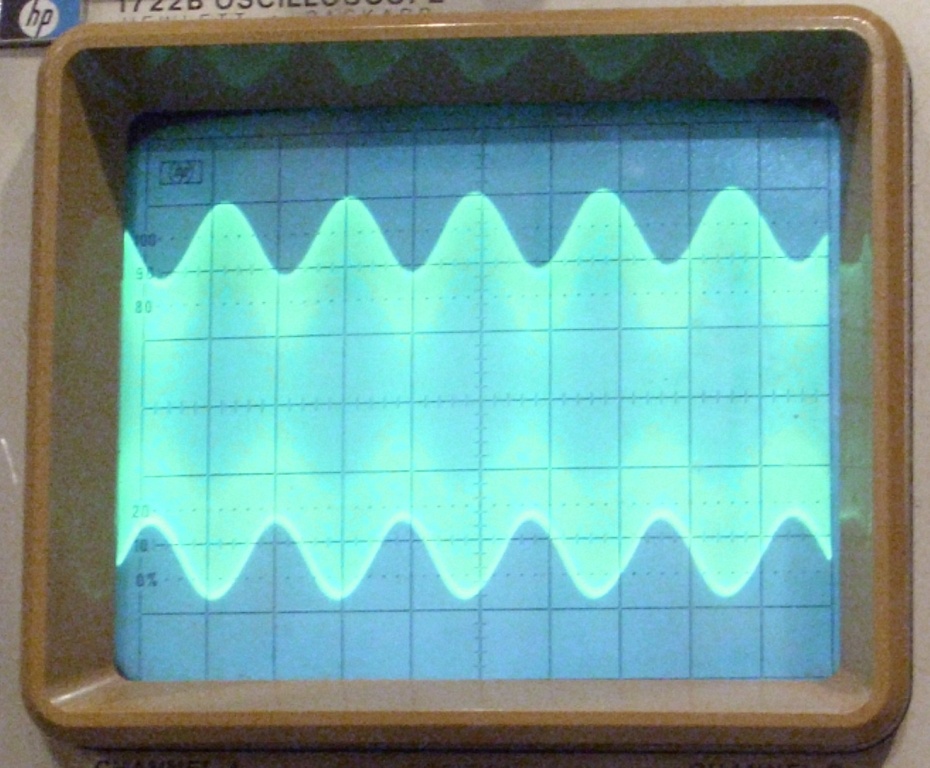

The AF oscillator valve uses a tuned choke (L7 and C24) to produce the 1 Kcs

frequency. The waveform is available on two terminals on the front panel for

external use. The AF level is rectified and shown on the front panel meter.

The AM modulation depth is set by adjusting the screen voltage of the AF

oscillator using the SET MOD. front panel control. When the level is set

to the CAL mark on the meter, the modulation depth is 30%, but it can be

varied from about 10% to about 60% modulation. There is an internal preset

control to calibrate the 30% level. AM modulation can be used on all bands.

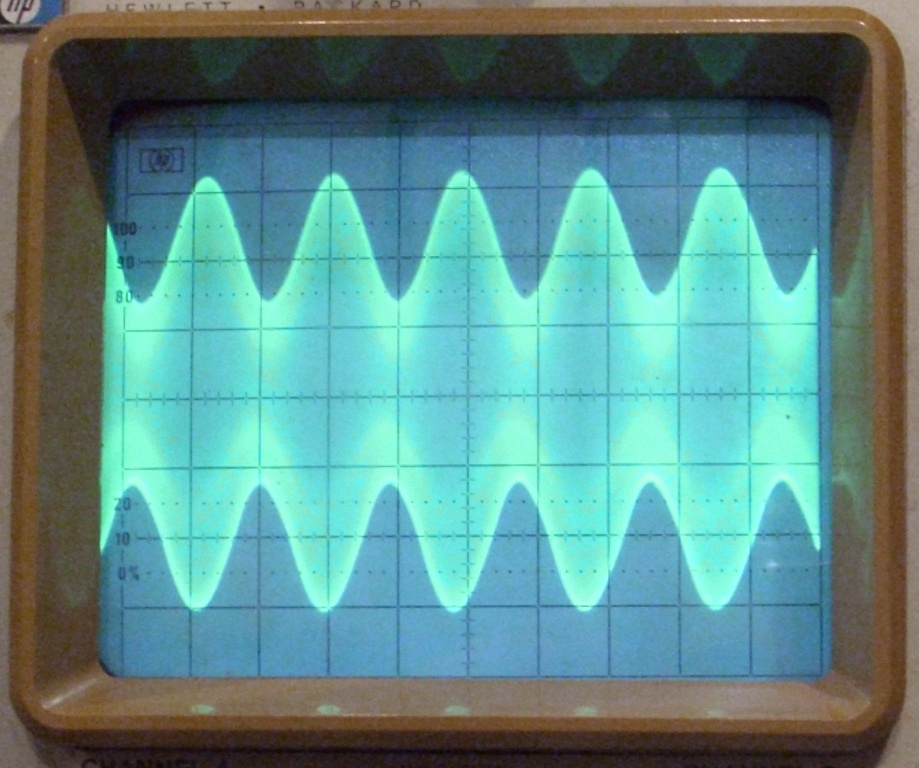

When switched to FM modulation, the front panel DEVIATION control can be

used to vary the FM from 0 to 40 Kcs. This control adjusts the amplitude

of the AF applied to the reactance valve in the RF oscillator module.

The reactance valve will act as a variable capacitance, and so vary the

frequency of the RF oscillator. However, the amount of capacitance required

to vary the RF oscillator frequency, is different for each RF frequency band,

and changes as you tune from end to end of the dial range. To keep the deviation

constant, two methods are used. There is a potentiometer ganged to the RF

frequency tuning control. As the frequency is changed from one end of the

dial to the other, the potentiometer adjusts the AF amplitude to keep the

deviation constant for that band. Secondly, there is a preset for each band,

to set the deviation amplitude for each particular band. The FM modulation can

only be used on the four bands above 2 Mcs.

The RF oscillator uses an RF transformer to couple the plate to the grid,

and a tuning capacitor to adjust the frequency. On the lower 3 bands,

a dual gang tuning capacitor is used. On the upper 4 bands, only 1 gang

is used, and the reactance valve is used in addition, but fixed for

AM modulation, and with AF applied for FM modulation. The RF oscillator

is coupled to a buffer, with a gain of approximately one. This then goes

to the output amplifier valve, with adjustable gain, controlled by the

screen supply variable from the SET CAR. front panel control, to set the

output level. This control is used to set the amplitude to the CAL mark

on the meter. AF is also applied to the screen to produce the AM modulation.

The RF then leaves the oscillator box though a fixed connector, and enters

the front panel attenuators. The RF amplitude is sampled at this point,

and rectified for indication on the front panel meter.

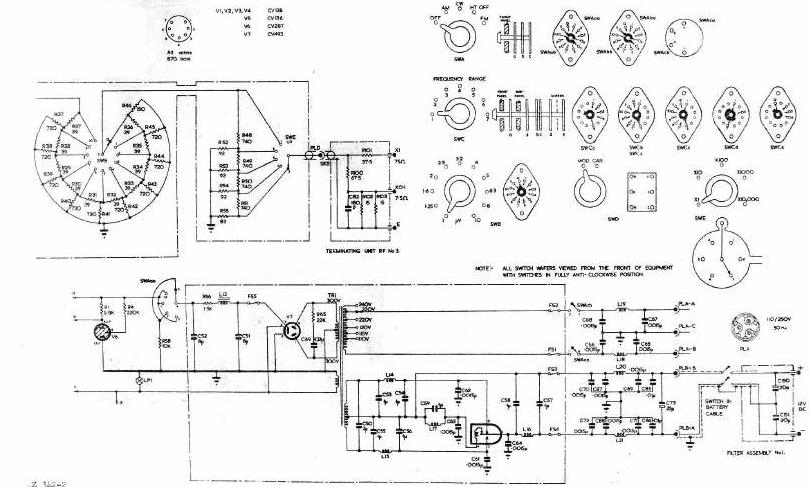

The attenuator consists of three parts. The first part is a “coarse” resistive

divider, with 5 positions, that produces 10 dB reduction at each position.

The second attenuator is a “fine” resistive divider, with 11 positions,

that provides 2 dB reduction at each position. The third attenuator is

external to the instrument, and is in the RF output cable. This is really

a terminator (TERMINATING UNIT No.3), and provides 75 ohm output or 7.5 ohm

output. The attenuators are labeled with a voltage scale (in black) and a

dB scale (in red). Using the black scale, the bottom attenuator control

can be set from 1 to 10 microvolts. The top attenuator, can then select

X1, X10, X100, X1000, and X10000. You have to do a mental calculation to

understand that this means that the output level is 1-10, then 10-100,

then 100-1000 microvolts. Then the next position is 1-10, then 10-100

millivolts. Using the alternative red scale, the bottom attenuator control

can be set from 0 to 20 dB in 2 dB steps. The top attenuator, can then

select 0, 20, 40, 60 and 80 dB. These can be added together to give a

100 dB range, but relative to what? It means that with no attenuation,

the output level is +100 dB greater than 1 microvolt. This is backwards

thinking from the way I use attenuators. I normally start with 0 dB as maximum

output, and then work down in negative dB steps. I found this dB scale

slightly confusing. It took some getting used to. I had to always remember

that with both knobs fully clockwise, there was maximum output. I gave up

trying to use dB, and only used the voltage scales. |